The stock maintained to ensure the adopted level of customer service is called the safety stock [Krzyżaniak 2008; Klimczak 2001]. In the literature, this stock is also defined as a part of the stock created in order to protect against the occurrence of higher demand than planned or to extend the delivery time of an order [Maternowska 2001]. The factors influencing the level of the safety stock are:

- Demand per unit of time D,

- Standard deviation of historical demand volumes or standard error in demand forecast σP

- Lead time LT,

- standard deviation of lead time σ LT.

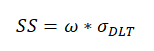

The level of the safety stock is determined from the formula1:

where:

ω – safety factor being a function of the adopted level of customer service,

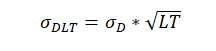

σDLT – standard deviation of demand during lead time calculated according to the formula:

where:

σDLT – standard deviation of demand during lead time,

D – average sales in the unit of time adopted for measurements.

σLT – standard deviation of the lead time,

σD – standard deviation of sales in the time unit used for measurements,

TL – lead time,

When analyzing the components of the formula for the standard deviation of demand during lead time, it is worth mentioning the impact of the standard deviation of sales in the cycle of stock replenishment on the degree of the safety stock [Gupta 1996; Chopra, Reinhardt and Dada 2004]. In the case of long delays in deliveries, it may turn out that this parameter has a very strong influence on the safety stock. In the case of suppliers for whom the purchase price is relatively low but the level of timely deliveries is low as well, it may turn out that the savings resulting from the low purchase price do not cover the costs associated with the need to maintain an increased level of the safety stock. In the literature on the subject there is a lively discussion on the impact of the length of the cycle of stockpile replenishment and its standard deviation on the level of the minimum inventory [Chopra, Reinhardt and Dada 2004; He, Xu and Hayya 2011]. The authors of the publication argue about the reduction of which of these parameters should be the first to focus on in order to reduce stock levels. They also argue that, due to lack of data, many people managing inventories in enterprises use the formula for the standard deviation of demand during lead time, assuming that the standard deviation of this cycle is equal to zero. The formula should then take the form of:

Failure to include the standard deviation of the replenishment cycle in the calculation of the safety stock may, however, leads to a shortage of products in the warehouse in situations where the supplier is late in completing the order.

The purpose of maintaining the safety stock is to cover the variability of demand, to meet demand during delivery delays and to provide an acceptable level of customer service. The level of the security stock is also an input to stock control according to two classical models: an information-based system and a periodic review system [Sarjusz-Wolski 2000; Cyplik 2001; Krzyżaniak 2008].

Referent:

- All formulas in subsections 2.2 were taken from [Willcox, B.,2002a] and [Willcox, B., 2002b] and [Willcox, B., 2003]. Where necessary, the applied symbolism was standardized.

_

Author of the article: Radosław Śliwka

Kontakt

61-707 Poznań ul. Libelta 27

Telefon

Na skróty

- Kiedy i w jaki sposób optymalizować procesy w firmie? Wykorzystaj spowolnienie w gospodarce do usprawnienia działań

- Optymalizacja procesów jako sposób na poprawę rentowności firmy i zadowolenia pracowników

- Pojemnikowy system składowania i ekspozycji towarów małogabarytowych, czyli AUTOSTORE

- Jeśli chcesz iść szybko, możesz to zrobić sam, jeśli chcesz pójść daleko, potrzebujesz do tego zespołu

- Po co komu analiza – czyli o wartości jaką wnosi analityk biznesowy do realizowanych projektów.